Understanding Gate Motor Diagrams

What Is a Gate Motor Diagram?

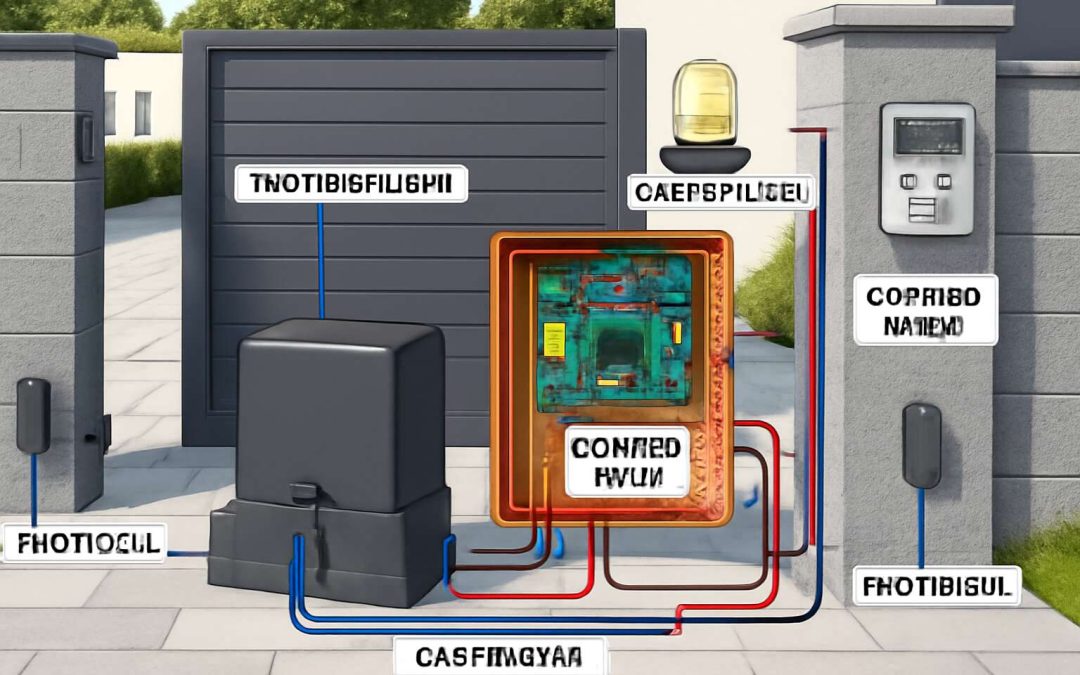

In the symphony of modern home automation, a gate motor diagram plays a pivotal role—yet, surprisingly, few homeowners truly grasp what these schematics entail. Think of it as the blueprint of a secret passage; once understood, it unveils the intricate dance of electrical components that bring your gate to life. A well-designed gate motor diagram illustrates not just the wiring, but also the logic behind the motor’s operation, ensuring seamless access and enhanced security for your property.

Understanding a gate motor diagram is akin to learning a new language—one that communicates the delicate balance between power and precision. It reveals how various parts such as the control panel, sensors, and safety features interconnect, providing a comprehensive view of the entire system. For those aspiring to troubleshoot or upgrade their existing gate automation, familiarity with this diagram is an invaluable asset.

To navigate these diagrams with ease, consider these essentials:

- Identifying the power source and control wiring

- Recognizing the safety devices embedded within the system

- Understanding the motor’s relay and switch configurations

In South Africa, where security is paramount, mastering the nuances of a gate motor diagram can transform a simple installation into an art form—merging functionality with finesse. With a keen eye on the schematic, your gate system becomes not just a barrier but a testament to sophisticated engineering and thoughtful design.

Importance of Knowing the Components

Understanding gate motor diagrams is an exercise in unlocking the hidden architecture of automated security systems, a task that demands both curiosity and precision. Each component within a gate motor diagram acts as a vital organ in the symphony of access control, where the failure or misinterpretation of a single element can compromise the entire operation. Recognizing the significance of these schematics elevates one’s ability to troubleshoot, upgrade, or simply appreciate the engineering finesse involved.

The importance of knowing the components for a gate motor diagram cannot be overstated. It’s not merely about wiring; it’s about deciphering a language that reveals the seamless integration of control panels, safety sensors, and motor relays. For example, understanding how the relay switch functions within the diagram illuminates how commands translate into motion—an intricate dance of electrical signals that culminates in effortless gate operation.

- Power sources and their connection points

- Sensors and safety devices embedded in the system

- Relay configurations that govern motor direction and speed

In South Africa, where security is woven into daily life, a comprehensive grasp of the gate motor diagram empowers homeowners and professionals alike. It transforms a simple schematic into a blueprint for reliability and security, allowing for innovations that are both functional and aesthetically refined. When you comprehend these components, you gain control over the very mechanism that safeguards your most valuable assets.

Types of Gate Motors and Their Diagrams

Understanding the different types of gate motors and their corresponding diagrams unlocks a new realm of possibilities in security and convenience. Each gate motor type—whether sliding, swing, or articulated—has a unique schematic that reveals its inner workings. These diagrams serve as maps, guiding technicians and homeowners alike through complex electrical pathways and control mechanisms with elegance and clarity. Recognizing the nuances in each gate motor diagram ensures seamless integration and efficient troubleshooting.

For instance, a sliding gate motor diagram typically emphasizes the motor’s connection to a track system, while a swing gate diagram highlights the pivot points and actuator placement. The diagrams often include:

- Power source connections

- Control panel wiring

- Safety sensors and their placement

By dissecting these schematics, one gains not only technical knowledge but also a deeper appreciation for the engineering artistry behind automated gates. Whether upgrading existing systems or installing new ones in South Africa’s security-conscious environment, a thorough grasp of these diagrams makes all the difference in creating a reliable, sophisticated barrier against intrusion.

Components of a Gate Motor System

Motor Unit

Imagine a gate motor system as the heartbeat of your driveway security—without it, your gates are just fancy fences. The motor unit is the core component that transforms electrical energy into mechanical force, making your gate swing or slide effortlessly. This vital piece includes a powerful motor, a gear system, and a drive mechanism, all working in harmonious chaos to ensure smooth operation. A detailed gate motor diagram reveals these intricate connections, showing how each part communicates and cooperates.

To understand its complexity, consider the motor unit as the command center. It’s responsible for interpreting signals from remote controls or keypads and translating them into action. The motor unit’s efficiency hinges on components like limit switches and safety sensors, which prevent accidental mishaps and ensure the gate stops precisely where it should. For a clearer picture, a typical gate motor diagram often highlights:

- Motor assembly

- Control board

- Limit switches

- Sensors and safety features

- Power supply connections

All these elements turn an ordinary motor into a reliable gate operator, capable of handling South Africa’s fluctuating power supply and rugged terrain—quite the feat! The gate motor diagram acts as a blueprint, guiding technicians through the labyrinth of components, ensuring your gate remains both functional and secure, no matter what the weather throws at it.

Control Panel

Within the intricate tapestry of a gate motor system, the control panel emerges as the command hub—a nexus where technology and precision converge. It’s more than just a box of circuits; it’s the brain that orchestrates seamless access, transforming rudimentary motion into a symphony of automation. The gate motor diagram portrays this control panel as a sophisticated interplay of components that communicate in a language of signals and responses, ensuring the gate’s movements are both synchronized and safe.

Essential elements within this control panel include the control board, which acts as the central processor, interpreting inputs from remote controls or keypads. Surrounding this core are various safety features such as emergency stop buttons, obstacle detection sensors, and limit switches, each vital in preventing accidents and preserving the integrity of the system. The power supply connections, often overlooked, are the lifeblood that sustains operation, especially in South Africa’s unpredictable electrical environment.

Understanding the layout and connections of a typical gate motor diagram reveals how these components form an unbreakable chain of communication. For instance, the control board relays signals to the motor, while sensors continuously monitor for obstructions, halting movement if necessary. This intricate web of interactions underscores the importance of a well-designed control panel—an essential for reliable, secure, and resilient driveway automation.

Power Supply

At the heart of every reliable gate motor system lies an unsung hero: the power supply. Without it, even the most advanced gate motor diagram falls silent—leaving your driveway vulnerable. In South Africa’s often unpredictable electrical landscape, a sturdy and well-designed power supply isn’t just a convenience; it’s an essential safeguard against system failure.

The power supply provides the necessary voltage and current to keep the entire automation system operational. It ensures that the control panel, sensors, and motor work in perfect harmony, transforming a simple gate into a fortress of security. A typical setup includes a dedicated circuit, surge protection, and backup options to maintain functionality during power outages—an absolute must in our region.

Within a gate motor diagram, components like the power supply connect directly to the control panel, creating a seamless flow of energy. This connection is crucial, as any disruption can compromise safety and efficiency. To visualize this interconnected web, consider key elements such as:

- AC/DC converters

- Surge protectors

- Battery backups

Understanding these elements and their placement within the gate motor diagram reveals the backbone of dependable driveway automation—powering not just the gate, but peace of mind itself.

Remote Controls and Keypads

Remote controls and keypads are the lifelines of a gate motor system, bridging the gap between convenience and security. In many South African homes, a reliable remote or keypad isn’t just a luxury—it’s a necessity, especially when battling unpredictable weather and power outages. These components allow homeowners to open and close their gates effortlessly, often with just a press of a button or a quick code entry.

Within a typical gate motor diagram, remote controls connect wirelessly to the control panel, sending signals that trigger the motor to operate. Keypads, on the other hand, are wired directly into the system, requiring a secure code to activate the gate. Both devices enhance safety and provide peace of mind, especially in rural settings where security is paramount.

To ensure seamless operation, many systems incorporate features such as rolling code technology or temporary access codes. These elements are vital in preventing unauthorized entry, reinforcing the importance of understanding the complete gate motor diagram. Proper placement and compatibility of remote controls and keypads are fundamental to creating a dependable driveway automation system—protecting what matters most.

Safety Sensors and Detectors

Safety sensors and detectors are the vigilant guardians within a gate motor system, silently ensuring the safety of everyone and everything in its vicinity. They serve as a critical link in the intricate web of a gate motor diagram, acting as the first line of defense against accidental injuries or vehicle collisions. When properly integrated, these sensors can detect motion, obstacles, or even small animals crossing the driveway, halting the gate’s movement instantly.

In many South African households, the importance of these components cannot be overstated, especially in rural areas where unexpected obstacles are common. The most common types include infrared beams, pressure sensors, and ultrasonic detectors, each serving a specific purpose to reinforce security and safety. When viewed within a gate motor diagram, their placement and wiring are crucial for seamless operation—ensuring that the system responds swiftly and accurately to the environment.

Understanding the role of safety sensors and detectors adds an essential layer to the overall system. They are the unseen heroes, working tirelessly behind the scenes to protect loved ones while maintaining the smooth flow of driveway automation. In essence, they turn a simple gate motor into a fortress of security—an unbreakable link in the chain of your home’s defensive perimeter.

Wiring and Connections

Behind the silent guardians of your driveway, a labyrinth of wiring and connections forms the backbone of a reliable gate motor system. These components, often hidden in shadows, are the unseen veins that breathe life into automation. Every wire, every junction is meticulously designed within the gate motor diagram to ensure harmony between power, control, and safety.

In essence, the wiring connects the control panel to the motor unit, safety sensors, and power supply, creating a symphony of signals that operate seamlessly. The control panel acts as the command center, orchestrating movement with precision. Meanwhile, the power supply fuels this entire mechanism, often concealed within a darkened recess but vital for uninterrupted operation.

To visualize the complexity, imagine a carefully crafted gate motor diagram where each connection and component plays a crucial role. For example, safety sensors and detectors are wired in series or parallel, ensuring the system responds instantly to obstacles crossing the driveway. This intricate network guarantees that your gate operates smoothly, securely, and with an almost supernatural awareness of its surroundings.

How to Read a Gate Motor Wiring Diagram

Symbols and Notations Used

Deciphering a gate motor diagram is like unlocking a secret language—each symbol, line, and notation whispers a story of electrical harmony. Imagine a tapestry woven with symbols that represent the heartbeat of your automated gate, guiding technicians and DIY enthusiasts alike through the labyrinth of connections with poetic clarity. To truly read a gate motor diagram, one must understand that every line signifies a wire, every symbol a component, and their interplay orchestrates seamless operation.

Symbols on a gate motor diagram are not mere doodles; they are carefully crafted icons—each with a purpose, each with a voice. For instance, a simple circle might denote a relay, while a zigzag line could represent a resistor. Understanding these notations transforms a confusing maze into a lucid map. Here are some common symbols you might encounter:

- Switch symbols indicating manual control points

- Arrowheads that show the direction of motor rotation

- Ground symbols representing safety grounding connections

By familiarizing yourself with these notations, you develop the ability to interpret the intricate dance of electrical signals within a gate motor diagram. It’s not just about reading lines; it’s about understanding the symphony of electricity that breathes life into your gate’s automation system, especially in the vibrant landscapes of South Africa, where robust and reliable gate systems are essential for security and convenience.

Identifying Power Sources

Understanding where your power source originates is fundamental when deciphering a gate motor diagram. Power sources are the lifeblood of any automation system, providing the energy necessary for smooth and reliable operation. In a typical gate motor diagram, identifying these sources involves following the lines that connect the control panel to the main power supply. This connection is often represented by a thick line or a distinctive symbol indicating power input. Recognizing these symbols ensures that the installation adheres to electrical standards and safety protocols, especially crucial in South Africa’s diverse environments.

Many diagrams use specific symbols to depict power sources, such as a simple line labeled “L” and “N” for live and neutral. Additionally, a ground symbol may appear, underscoring the importance of safety grounding connections. To accurately locate these, look for the main power connection point—often near the control panel—and trace the wiring back to the power outlet or supply. Ensuring that the gate motor diagram correctly shows these power connections is vital; it guarantees the system’s operational integrity and safety, allowing technicians and DIY enthusiasts to work with confidence and clarity.

Tracing the Control Circuit

Reading a gate motor diagram isn’t merely about recognizing symbols; it’s about unraveling the hidden language of automation. When tracing the control circuit, the first step is to follow the wiring from the control panel—often the brain of the system—back to the motor and power sources. This path reveals how commands, like remote presses or keypad entries, translate into movement. The circuit’s flow is like a pulse, energizing relays and activating the motor with precision.

To decode this, look for connections marked with distinctive symbols—these mark switches, sensors, or safety devices that influence the gate’s operation. An ordered approach helps:

- Identify the control panel’s wiring terminal.

- Trace the wiring back to the power source, noting the live (L) and neutral (N) lines.

- Follow the control wires to the safety sensors and alarm systems.

- Check the connections to remote controls or keypads, often depicted with specific symbols or labels.

This methodical tracing uncovers the intricate web of signals that make your gate work flawlessly. Understanding how to read a gate motor diagram opens the door to troubleshooting, ensuring safety, and maintaining smooth operation—especially vital in South Africa’s diverse environments where reliability is paramount!

Understanding Safety Features

Understanding the safety features embedded within a gate motor diagram isn’t just about avoiding electrocution or gate mishaps; it’s about ensuring peace of mind in a world where technology sometimes feels more temperamental than a South African traffic jam. When deciphering a gate motor diagram, paying close attention to safety sensors and detectors is paramount—these are the unsung heroes that prevent accidents before they happen.

Look for symbols representing safety devices—these might include photoelectric sensors, safety edges, or obstacle detectors. These components work silently, ensuring that the gate halts if an object or person crosses its path. To fully grasp how safety features integrate into the control circuit, consider this ordered approach:

- Trace the wiring leading from safety sensors back to the control panel.

- Identify how signals from these sensors influence the relay system.

- Check the connections to emergency stop buttons or safety alarms, often depicted with distinctive symbols.

Decoding this web of connections within a gate motor diagram reveals how safety isn’t just a feature—it’s woven into the very fabric of automation. Mastery over reading a gate motor diagram not only empowers troubleshooting but also safeguards lives in South Africa’s diverse environments, where reliability is not just preferred but essential!

Common Gate Motor Wiring Configurations

Single-Phase vs. Three-Phase Motor Wiring

When it comes to gate motor diagram configurations, understanding the fundamental differences between single-phase and three-phase wiring can be the key to unlocking reliable and efficient operation. In South Africa, where power infrastructure varies across regions, selecting the correct wiring setup ensures your gate motor functions seamlessly under diverse conditions. A single-phase gate motor diagram typically involves simpler wiring—just two wires connecting to the power source—making installation straightforward for residential applications. However, for larger or commercial gates, a three-phase gate motor diagram offers enhanced power delivery and smoother operation, albeit with more complex wiring requirements.

Recognizing these distinctions is vital. A gate motor diagram for single-phase motors usually includes a basic connection to the power supply and control circuit, whereas three-phase configurations incorporate additional phases, increasing efficiency and torque. For those venturing into advanced gate automation, understanding the nuances of these wiring configurations can mean the difference between a reliable system and frequent maintenance issues. Remember, each setup has its unique symbols and notations, which are essential to interpret accurately when tracing wiring paths or troubleshooting. Whether you’re installing a simple residential gate or a robust commercial barrier, the right knowledge of wiring configurations ensures your gate motor diagram remains a trusted blueprint for success.

Automatic vs. Manual Control Wiring

In the realm of gate automation, the choreography of electrical signals is both an art and science — a delicate dance that transforms static barriers into seamless gateways. When exploring common gate motor wiring configurations, the distinction between automatic and manual control wiring becomes a symphony of purpose and precision. Automatic systems, like silent sentinels, respond to remote commands and sensors, weaving convenience into the fabric of everyday life. Manual controls, however, embody the timeless trust of physical intervention, where a simple switch commands the opening and closing of the portal.

Understanding these nuances is vital for ensuring the integrity of your gate motor diagram. For automation enthusiasts, a well-designed wiring setup might include control panels linked to safety sensors and remote controls, orchestrating a harmonious flow of power and signals. Conversely, manual configurations rely on straightforward wiring paths, often involving switches and safety interlocks. The key is recognizing how each wiring approach influences reliability and safety, especially under South Africa’s diverse power conditions. Whether you’re upgrading or installing anew, appreciating these common gate motor wiring configurations ensures your system remains resilient and efficient.

Backup Power Wiring

Backups in the realm of gate motor wiring are less about superhero capes and more about ensuring your driveway isn’t left wide open during a power outage. In South Africa’s often unpredictable electrical landscape, backup power wiring for gate motors isn’t just a luxury—it’s an essential safeguard. When the main power fails, a well-designed backup system kicks into gear, preventing your gates from becoming stubborn barriers rather than welcoming portals.

One common configuration involves integrating a UPS (Uninterruptible Power Supply) or a generator with the gate motor diagram. This setup ensures seamless operation, whether you’re battling load shedding or unexpected outages. A typical backup wiring for gate motors includes a dedicated circuit that activates automatically, preserving the convenience of automatic control, even in blackouts.

For those who prefer a more organized approach, a

- transfer switch

- manual override switch

can be incorporated into the wiring. These elements work in harmony with the control panel to provide reliable power transfer, maintaining safety and security without a hitch. When designing your gate motor diagram, always remember that a resilient backup system is the unsung hero of dependable gate automation in South Africa’s challenging power environment.

Troubleshooting Gate Motor Diagrams

Common Wiring Issues

When dealing with a gate motor diagram, troubleshooting common wiring issues can feel like navigating a labyrinth. Sometimes, a simple misconnection or a loose wire can cause the entire system to malfunction, leaving property owners frustrated and vulnerable. It’s vital to recognize that most problems stem from overlooked details in the wiring connections, which are often outlined in the gate motor diagram. A thorough understanding of the diagram can help identify where the fault lies, whether it’s a power supply hiccup or a control circuit disruption.

Common wiring issues include broken or corroded connections, incorrect terminal placement, or damaged control panels. These issues can be diagnosed by carefully tracing the wiring according to the gate motor diagram, paying close attention to the safety sensors and control panel connections. Sometimes, a simple inspection reveals that a wire has come loose or a connector has corroded, causing the system to stop working unexpectedly. Staying vigilant in checking these details ensures reliable operation, especially in rural areas where gate automation is vital for security and convenience.

Diagnosing Electrical Failures

When troubleshooting electrical failures in a gate motor system, the key to success often lies in the humble yet mighty gate motor diagram. This visual roadmap reveals the intricate web of wires, connections, and components that keep your gate functioning smoothly—or cause it to throw a tantrum. Without a clear understanding of the diagram, diagnosing faults can feel like trying to find a needle in a haystack, especially when spontaneous system failures occur.

Start by methodically tracing the wiring according to the gate motor diagram, paying close attention to the control circuit and safety sensors. Often, a loose wire or a corroded connector is the culprit, silently sabotaging your gate’s performance. An effective troubleshooting approach involves inspecting each connection, ensuring that terminal placements are correct and that no wires are frayed or damaged. Sometimes, the simplest fix is just a thorough visual inspection guided by the gate motor diagram, revealing issues that might otherwise be overlooked.

For those who enjoy a structured approach, an ordered list can be invaluable:

- Check the power supply connection, ensuring voltage matches the specifications in the gate motor diagram.

- Trace the control circuit wiring, confirming all connections align with the diagram’s notations.

- Inspect safety sensors and detectors, verifying they’re clean, correctly aligned, and wired properly.

- Identify any broken or corroded wires that could interrupt the flow of electricity.

Understanding how each component in the gate motor diagram interacts helps uncover hidden faults — like a missing link in a chain. Whether it’s a malfunctioning control panel or a compromised backup power wiring, each element’s role is mapped out in the diagram, transforming a confusing mess into a clear pathway. So, next time your gate decides to ignore your commands, remember: a well-read gate motor diagram is your best friend in unraveling the electrical enigma.

Signs of Incorrect Wiring

In the labyrinth of electrical mysteries that can plague your gate system, signs of incorrect wiring often emerge as subtle whispers rather than loud alarms. A miswired gate motor diagram can turn your smooth-operating gate into a stubborn sentinel, refusing to obey commands or, worse, causing safety hazards. Spotting these signs early can save you hours of frustration and costly repairs.

Look out for inconsistent operation—where the gate hesitates, stalls, or moves unpredictably. Sometimes, you might notice a flickering control panel or unexpected tripping of circuit breakers, clues pointing toward wiring issues. A common culprit is reversed connections or loose wires that, when traced back to the gate motor diagram, reveal themselves in the form of misplaced terminals or faulty connections.

To truly understand the subtle cues of wiring mishaps, consider this approach:

- Inspect all wiring against the gate motor diagram, ensuring each wire is correctly placed and firmly connected.

- Check for signs of corrosion or damage on connectors, which often mimic wiring faults.

- Test safety sensors and detectors to confirm they’re wired precisely as indicated—any deviation can cause erratic behavior.

In the realm of gate automation, the tiniest wiring error can cause a cascade of faults—highlighting the importance of a keen eye and a reliable gate motor diagram. When the gate acts up, it’s often just a matter of uncovering that the wiring isn’t quite right, hidden beneath the surface of seemingly innocent connections. Remember, understanding these signs and the underlying wiring layout is the key to restoring harmony to your gate system.

Safety Guidelines for Working with Gate Motor Diagrams

Ensuring Proper Electrical Safety

Working with a gate motor diagram demands more than just basic technical know-how; it requires a vigilant approach to electrical safety. South African installations often involve complex wiring that, if mishandled, can lead to costly damage or dangerous malfunctions. The key is to recognize the importance of proper grounding and insulation—these are the silent guardians of safety in every gate motor setup.

Before diving into any work, ensure the power source is completely isolated. Use a reliable circuit tester to confirm the absence of voltage, preventing accidental shocks. Remember, a detailed gate motor diagram isn’t just a schematic—it’s a blueprint for safe, effective installation and troubleshooting. Keep in mind the following essential safety guidelines:

- Always wear insulated gloves and safety goggles to shield against unforeseen electrical hazards.

- Verify all wiring connections against the gate motor diagram to prevent incorrect wiring that could compromise safety features.

- Use appropriate tools designed for electrical work, avoiding shortcuts that might jeopardize safety or the integrity of the system.

In the pursuit of a secure gate automation system, respecting these precautions isn’t just prudent; it’s essential. Understanding the intricacies of your gate motor diagram can be the difference between seamless operation and a hazardous failure lurking behind the scenes.

Understanding Emergency Shutdown Circuits

When working with a gate motor diagram, understanding the emergency shutdown circuits is paramount—especially in a country where power fluctuations can be as unpredictable as a summer thunderstorm. These circuits are the safety net, providing a quick disconnect in case of malfunction or danger. Recognizing their placement and function within the gate motor diagram can be the difference between a swift, safe resolution and a costly mishap.

Safety guidelines must be adhered to meticulously. Always verify that the emergency shutdown circuit is properly integrated into the wiring, ensuring it can be activated instantly when needed. An effective way to do this is to test the circuit regularly, confirming it trips reliably without interference. Remember, a well-designed gate motor diagram not only guides installation but also emphasizes safety features like emergency shutdowns—these are the unsung heroes of secure automation systems.

In practical terms, it’s wise to keep the wiring clear and organized around these critical circuits. Use a

- labelled wiring system

to prevent confusion during maintenance or troubleshooting. The goal is to ensure that in an emergency, the shutdown command acts swiftly, halting all motion and preventing potential accidents. After all, in the realm of gate automation, safety isn’t just a feature—it’s a fundamental principle woven into every gate motor diagram.

Legal and Compliance Considerations

Safety and compliance are the bedrock of any successful gate automation installation—especially when dealing with a complex gate motor diagram. In South Africa, adherence to legal standards isn’t just a recommendation; it’s a mandate that safeguards both operators and property. Ensuring that your gate motor diagram aligns with the national electrical and safety regulations can prevent costly penalties and, more importantly, avert accidents.

A crucial aspect of working with a gate motor diagram involves understanding the legal obligations surrounding electrical safety. It’s imperative to verify that all wiring and safety features, such as emergency shutdown circuits, meet local standards. These circuits must be easily accessible and reliable, providing a swift response during emergencies.

- Always use certified components that comply with South African electrical codes.

- Ensure that wiring is neatly organized and clearly labeled to facilitate inspections and maintenance.

- Regularly review and test safety features to guarantee ongoing compliance and functionality.

Failure to observe these guidelines not only compromises safety but could also lead to legal repercussions. In the realm of gate automation, a meticulous approach to the gate motor diagram isn’t just good engineering—it’s a vital legal safeguard that ensures safety remains at the forefront of every operation.

Resources and Tools for Interpreting Diagrams

Recommended Wiring Diagrams and Manuals

Navigating the world of gate motor diagrams can seem daunting, but having the right resources and tools makes all the difference. Accurate interpretation of wiring diagrams and manuals is essential for ensuring safe and efficient installation or troubleshooting. For professionals and enthusiasts alike, accessing comprehensive resources can turn complex schematics into manageable tasks.

Recommended wiring diagrams and manuals often come with detailed annotations, symbols, and notations that clarify each connection point. Investing in high-quality tools such as multimeters, wire strippers, and circuit testers can elevate your diagnostic capabilities. These tools allow for precise voltage measurements and continuity checks, vital for verifying the integrity of a gate motor diagram.

- Online technical libraries and manufacturer websites provide invaluable, up-to-date gate motor diagrams.

- Specialized software can help visualize wiring configurations, making complex diagrams more accessible.

- Community forums and professional networks often share insights and troubleshooting tips that complement official manuals.

By combining authoritative resources with reliable tools, it becomes possible to decode even the most intricate gate motor diagram, ensuring your projects meet safety standards and perform flawlessly in South Africa’s unique environment.

Tools for Electrical Testing

Interpreting a gate motor diagram requires more than just a cursory glance at the schematic; it demands precision, patience, and the right set of tools. In South Africa’s diverse environment, where electrical standards and installation conditions vary, having reliable resources is crucial. Technical libraries and manufacturer websites are treasure troves of up-to-date gate motor diagrams, offering detailed annotations and symbols that demystify complex wiring layouts.

To enhance your diagnostic capabilities, investing in quality tools such as multimeters, wire strippers, and circuit testers is essential. These devices enable accurate voltage measurements and continuity checks, making it easier to verify connections within a gate motor diagram. For instance, a multimeter can help confirm the integrity of power sources or detect faulty wiring that might otherwise go unnoticed.

Visualizing the wiring configurations becomes significantly easier with specialized software designed for electrical schematics. Additionally, engaging with community forums and professional networks allows you to exchange insights and troubleshooting tips that complement official manuals. Combining these resources and tools transforms intricate gate motor diagrams into manageable, safe, and efficient installation or repair projects in South Africa’s unique electrical landscape.

Professional Assistance

When it comes to interpreting a gate motor diagram, professional assistance can be an invaluable asset—especially in South Africa’s intricate electrical landscape. While schematics may seem like an arcane language at first glance, seasoned technicians know that having access to expert support can turn a daunting task into a straightforward endeavor. Engaging with qualified electricians or specialized service providers ensures not only accuracy but also adherence to local safety standards, which are paramount in our ever-evolving regulatory environment.

Moreover, tapping into the expertise of professionals often reveals insights that diagrams alone cannot convey. They can identify subtle wiring nuances, troubleshoot complex control circuits, and provide tailored recommendations that align with South Africa’s particular electrical standards. For those keen on DIY diagnostics, collaborating with experienced specialists can prevent costly mistakes and safeguard both property and personnel.

In addition, accessing resources such as dedicated technical libraries, manufacturer websites, or industry forums can complement professional assistance. These platforms often host comprehensive gate motor diagram archives, annotated with tips that demystify even the most intricate wiring configurations. Ultimately, combining expert help with reliable resources empowers you to interpret a gate motor diagram with confidence, turning complexity into clarity—an essential step in maintaining safe and efficient gate automation systems in South Africa’s unique environment.